Understanding the Basics: What is Predictive Maintenance?

In today’s fast-paced digital world, system downtime isn’t just an inconvenience – it’s a costly nightmare. Think of predictive maintenance as your IT infrastructure’s personal health monitor. Just like how our smartwatches track our health metrics, predictive maintenance uses advanced algorithms to monitor your system’s vital signs.

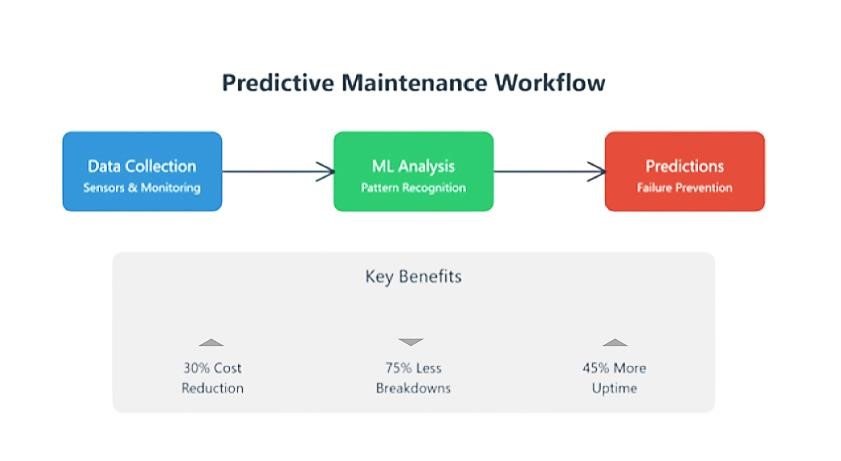

Here’s what makes it different from traditional maintenance approaches:

⦁ Real-time monitoring instead of fixed schedules

⦁ Data-driven decisions rather than guesswork

⦁ Proactive problem solving versus reactive fixes

The Role of Machine Learning in Predictive Maintenance

Machine learning transforms raw data into actionable insights. By analyzing patterns from various data sources, ML algorithms can predict potential failures before they happen. For instance, when a server starts showing unusual CPU temperature patterns, the ML model can flag it as a potential cooling system failure.

Key ML techniques used include:

⦁ Anomaly detection algorithms

⦁ Classification models

⦁ Time series analysis

⦁ Regression models for failure prediction

Implementation Strategy: Getting Started

Starting your predictive maintenance journey doesn’t have to be overwhelming. Begin with these essential steps:

⦁ Data Collection Infrastructure

⦁ Set up sensors and monitoring tools

⦁ Implement data storage solutions

⦁ Establish data quality protocols

⦁ Model Selection and Training

⦁ Choose appropriate algorithms

⦁ Train models on historical failure data

⦁ Validate results with test datasets

Benefits and ROI: Making the Business Case

The financial impact of predictive maintenance is substantial. Companies implementing these systems typically see:

⦁ 25-30% reduction in maintenance costs

⦁ 70-75% decrease in system breakdowns

⦁ 35-45% reduction in downtime

But it’s not just about numbers. Consider the improved customer satisfaction when your services maintain consistent uptime and performance.

Common Challenges and Solutions

Even the best technologies come with their hurdles. Here are the most common challenges and their solutions:

⦁ Data Quality Issues

⦁ Implement robust data validation

⦁ Use data cleaning pipelines

⦁ Regular sensor calibration

⦁ Integration Challenges

⦁ Start with pilot projects

⦁ Use APIs for seamless integration

⦁ Ensure scalability from the beginning

Best Practices for Success

Success in predictive maintenance isn’t just about technology – it’s about process and people too. Here’s what successful implementations have in common:

⦁ Clear Documentation

⦁ Maintain detailed maintenance logs

⦁ Document model performance metrics

⦁ Keep track of system improvements

⦁ Team Training

⦁ Regular skill updates

⦁ Cross-functional knowledge sharing

⦁ Clear communication protocols

Future Trends and Innovations

The future of predictive maintenance is exciting. We’re seeing emerging trends like:

⦁ Edge computing for faster processing

AI-powered visual inspections

⦁ Digital twins for better simulation

⦁ Integration with 5G networks

Real-World Success Stories

Let’s look at some concrete examples. A major data center implemented ML-based predictive maintenance and achieved:

⦁ 40% reduction in unexpected downtime

⦁ $2.5 million annual savings

⦁ 50% improvement in maintenance efficiency

Conclusion

Predictive maintenance isn’t just a buzzword – it’s a crucial investment for modern IT infrastructure. By combining ML capabilities with strategic implementation, organizations can significantly reduce costs while improving reliability.